Stop Costly Mislabeling Before It Starts: Smart Label Roll Verification for Food Packaging

A single mislabeled product can trigger an FDA investigation, force a costly recall, and damage your brand reputation. In food and consumer goods packaging, getting the label right isn't just about quality—it's about protecting your business from million-dollar mistakes.

The solution? Automated label roll verification that catches errors before the first product is ever labeled.

The Hidden Cost of Manual Label Checking

Most food manufacturers still rely on visual inspection to catch labeling errors. But human inspectors can't keep up with modern production speeds, and they miss critical issues like:

- Subtle barcode quality problems that cause scanning failures

- Template mismatches in multi-language packaging

- Orientation errors that lead to upside-down labels

- Pre-printed content that doesn't match the current batch

By the time these errors are discovered, thousands of products may already be mislabeled.

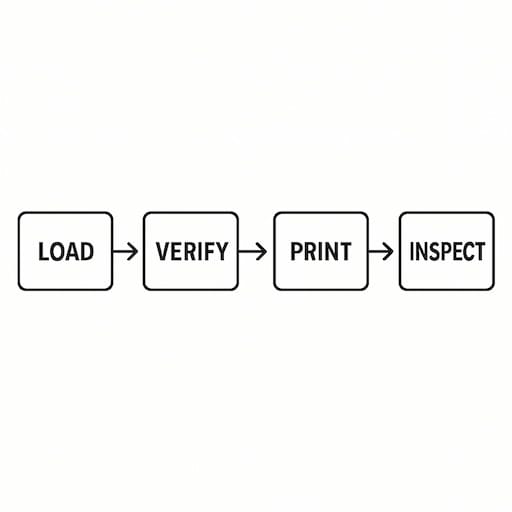

How Smart Verification Works

Modern label roll verification systems check everything before production starts:

Pre-Production Verification: The system confirms the correct roll type, verifies pre-printed content matches templates, and validates barcode quality—all before the roll enters the printer.

Loading Accuracy: Sensors confirm operators have loaded the right roll in the correct orientation, preventing simple but costly setup errors.

Real-Time Monitoring: Throughout production, continuous machine vision inspection catches printing issues immediately and stops the line automatically when problems occur.

| Verification Stage | What Gets Checked | Technology Used | Benefit |

|---|---|---|---|

| Pre-Load Check | Roll type, content, barcode quality | MV-4000 Vision System | Prevents wrong rolls from entering production |

| Loading Verification | Proper placement, orientation | NX1 Controller + Sensors | Ensures correct setup before printing starts |

| In-Line Monitoring | Print quality, template matching | Integrated Vision + Control | Catches errors immediately during production |

| Data Logging | Batch tracking, quality metrics | NX1 + MES Integration | Enables full traceability and compliance reporting |

Proven Results in Food Manufacturing

Major Food Producer Success

Working with Omron, a leading food manufacturer implemented Omron's V275 inspection system and achieved near-zero mislabeled products while handling multi-language formats seamlessly.

Food Packaging Equipment Manufacturer

A major equipment manufacturer in the food packaging industry leveraged Sysmac solutions to set new benchmarks for machine performance, achieving faster setup times, reduced waste, and improved overall equipment efficiency through advanced data capabilities and seamless integration.

The Technology Behind Smart Verification

NX1 Series Controllers: High-speed edge controllers like the NX102 and NX1P that integrate logic, motion, safety, and data connectivity in one unit. With 1ms cycle times, they provide instant response to quality issues.

MV-4000 Smart Cameras: Industrial vision systems capable of inspecting 4,000-14,000 parts per minute, handling barcode verification, text recognition, and layout checks simultaneously.

Sysmac Platform: Unified development environment that enables rapid format changeovers—template switches happen in under a minute for multi-SKU production runs.

Why Automation Wins

Speed: Inspects at full production speed without creating bottlenecks

Consistency: Maintains the same high standards across all shifts

Compliance: Automatically logs data for FDA, CFIA, and ISO requirements

Flexibility: Handles multiple languages and formats with quick changeovers

ROI That Makes Sense

The cost of implementing label verification is typically recovered within months through:

- Prevented recalls and associated costs

- Reduced waste from mislabeled products

- Improved throughput from automated inspection

- Lower labor costs for quality control

Consider that a single recall can cost millions in direct expenses plus immeasurable brand damage—making verification systems one of the smartest investments in food packaging.

Ready to Eliminate Labeling Errors?

At Proax Technologies, we've helped food and consumer goods manufacturers across North America implement bulletproof labeling systems. From assessment through installation, we ensure your verification system delivers maximum protection and ROI.

Contact our automation experts to discuss how label roll verification can protect your brand and streamline your packaging operations.